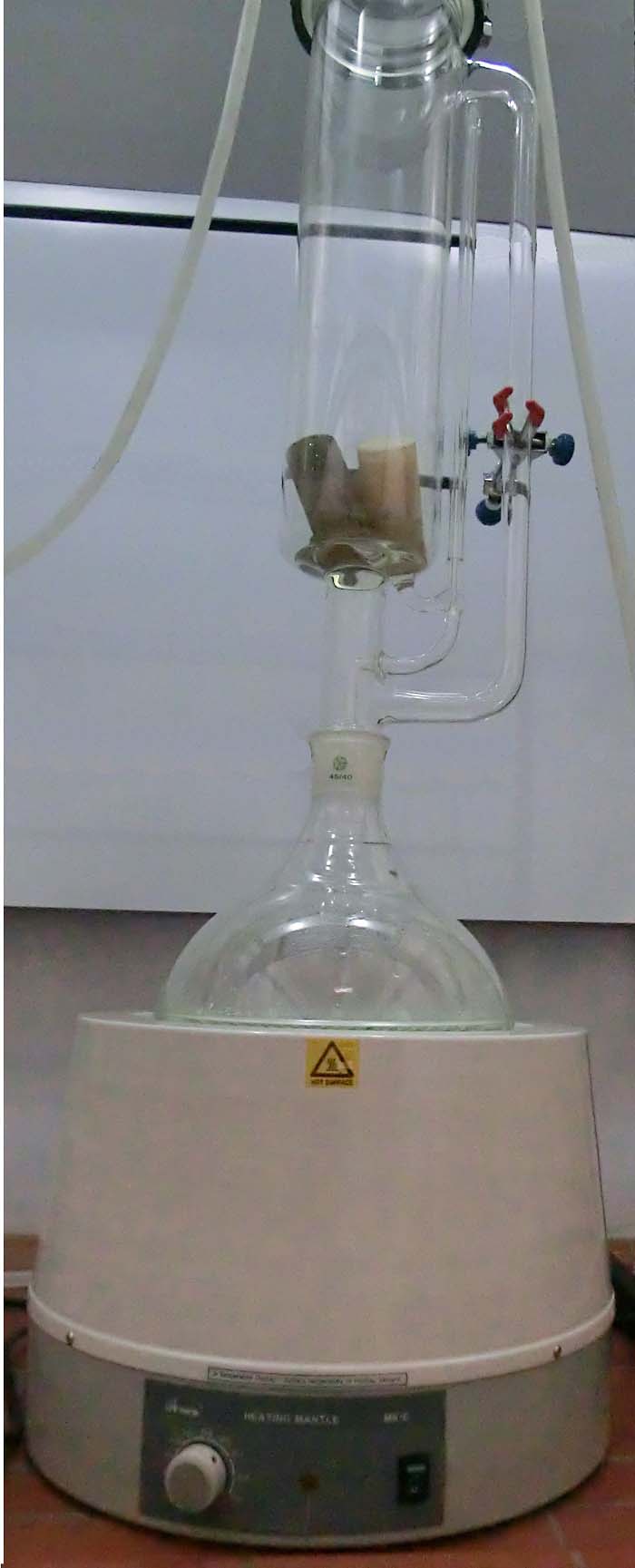

In this apparatus, The solvent is heated to reflux. The solvent vapour travels up a distillation arm, and floods ind-soxhlet into the chamber housing the thimble of solid. The condenser ensures that any solvent vapour cools, and drips back down into the chamber housing the solid material. The chamber containing the solid material slowly fills with warm solvent. Some of the desired compound dissolves in the warm solvent. When the Soxhlet chamber is almost full, the chamber is emptied by the siphon. The solvent is returned to the distillation flask. The thimble ensures that the rapid motion of the solvent does not transport any solid material to the still pot. This cycle may be allowed to repeat many times, over hours or days.

Industrial Version

- Core sample diameter: up to 4" for industrial model

- Core sample length: up to 8" for industrial model

- Extractor capacity: 3 liters for industrial model

- Boiling flask: 5 liters for industrial model

- Heating temperature: up to 400°C

- Water cooling system: 0.5 to 3 liters per minute, 18°C

- Power supply: 220 VAC 50 Hz

Educational Version

- Core sample diameter: up to 1.5 for educational model

- Core sample length: up to 4 for educational model

- Extractor capacity: 250 cc for educational model

- Boiling flask: 500 cc for educational model

- Heating temperature: up to 400°C

- Water cooling system: 0.5 to 3 liters per minute, 18°C

- Power supply: 220 VAC 50 Hz

In order to find out more about soxhelt extractor, contact us with the subject of "soxhelt extractor".