BBS In-Line Manifold Valve provide a leak checked and pressure tested single point solution when assembled to pressure transmitters. The in-line, compact design is available with a lightweight block and bleed or two-valve configurations. Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

BBS In-Line Manifold Valve provide a leak checked and pressure tested single point solution when assembled to pressure transmitters. The in-line, compact design is available with a lightweight block and bleed or two-valve configurations. Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

Features

- Pressure range: up to 15,000 psi

- Temperature range: up to 150°C

- Flowing lines: 1/8 and 1/4 in outer diameter

- Wetted materials: Stainless steel 316L

Technical Specifications

Material selection

BBS provides a variety of BBS product with various product options and configurations including materials of construction that can be expected to perform well in a wide range of applications. The BBS product information presented is intended as a guide for the purchaser to make an appropriate selection for the application. It is the purchaser’s sole responsibility to make a careful analysis of all process parameters (e.g., all chemical components, temperature, pressure, flow rate, abrasives, contaminants), when specifying product, materials, options and components for the particular application. Emerson is not in a position to evaluate or guarantee the compatibility of the process fluid or other process parameters with the product, options, configuration or materials of construction selected. For more information on material compatibility, refer to the Material Selection and Compatibility Considerations for process Pressure Transmitters.

| Packing | Seat | Pressure and temperature ratings |

| PTFE | Integral | 15000 psi at –40 to 300 °F (1034 bar at –40 to 149 °C) or 4500 psi at 400 °F (310 bar at 204 °C) |

| Graphite | Integral | 10000 psi at –40 to 300 °F (690 bar at –40 to 149 °C) or 1700 psi at 750 °F (117 bar at 399 °C) |

Ordering

Ordering information

BBS Manifold Valve can be ordered as a stand-alone product or as an integrated assembly attached to any type of process transmitter.

Order a In-Line Manifold Valve Procedure

- Reference the Selection guide for assistance on choosing the type of Manifold Valve.

- Specify a completed model number by referencing the applicable ordering table for the selected Manifold Valve type:

BBS 11-15 In-Line Manifold Valve Ordering Data Table

| Model | Product description | ||||

| 11-15 | In-Line Manifold Valve | × | |||

| Design class | |||||

| E | Enhanced | × | |||

| Manifold Valve style | |||||

| T9 | 90 ° Valve Position Female Threaded | × | |||

| T1 | 180 ° Valve Position Female Threaded | ||||

| Manifold Valve type | |||||

| 1 | Block-and-Bleed | ||||

| 2 | Two-valve | × | |||

| Material | Body | Bonnet | Stem | Tip | |

| S1 | 316L SST | 316L SST | 316L SST | 316L SST | × |

| S2 | 316L SST | 316L SST | 316L SST | UNS 17400 | |

| Process connection | |||||

| A | ⅛–18 Female NPT process connection | ||||

| B | ¼–18 Female NPT process connection | × | |||

| Packing material | |||||

| 1 | PTFE | × | |||

| 2 | Graphite-based | ||||

| Valve seat | |||||

| 1 | Integral | × | |||

The signed offerings (×) represent the most common options and should be selected for best delivery. The non-starred offerings are subject to additional delivery lead time. Order Example:

11-15 E T9 2 S1 B 1 1 (11-15 Valve Model, Two Valve with 90 ° Style, SS316L material and PTFE Packing )

Technology

BBS Pressure-Lock technology

Exclusively featured on the BBS 11-15 In-Line Manifold Valve

Exclusively featured on the BBS 11-15 In-Line Manifold Valve

■ Two-piece valve stem design provides easier handle turn operation

■ Needle-tip safety back seating ensures operator safety during process blowout events

Enhanced reliability

■ Process-isolated stem threads increase overall valve life

Simplified operation

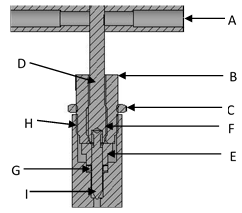

■ A. Removable handles - allows for a quick way of adding security and reducing tampering.

■ B. Packing nut - allows for smooth adjustment of stem packing.

■ C. Nut for stem tightness.

■ D. Two-piece stem design with non-rotating tip - provides smooth ergonomic operation, reduces potential leak paths, and decreases overall wear, extending valve life.

Increased operator safety

■ E. Safety back seating - provides integral blowout protection.

Enhanced reliability

■ F. Stem threads isolated from process fluid – increase equipment life and operator safety.

■ G. Modular packing – located below stem threads to isolate thread from process fluid, preventing corrosion.

■ H. Bonnet threads isolated from process fluid – improves corrosion resistance and equipment life with metal-to metal, bonnet-to-body seal.

■ I. One-piece needle tip stem – ensure seal integrity over wide range of pressures and temperatures.

Note

For more information on the Pressure-Lock Valve, reference BBS Pressure-Lock Valve Configuration.

In order to find out about various models of HPHT valves, contact us with the subject of "HPHT valve models".